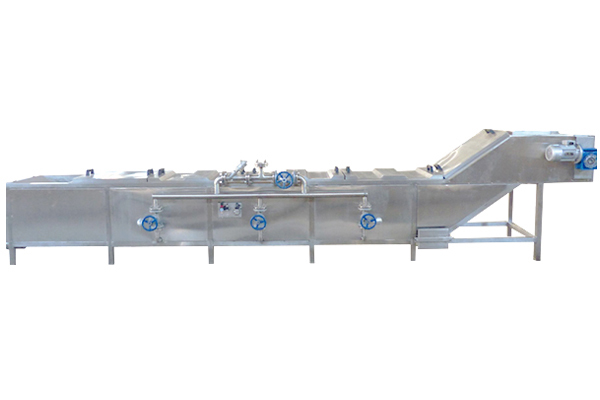

Pasteurization line

Auther:407

Pubdate:2019-12-28 03:37:46

The principle of sterilization is that in a certain temperature range, the lower the temperature, the slower the bacterial reproduction; The higher the temperature, the faster the reproduction. But if it gets too hot, the bacteria will die. Different bacteria have different optimum growth temperature and heat and cold resistance. Pasteurization is to take advantage of the pathogen is not very heat-resistant characteristics, with appropriate temperature and heat preservation time to deal with, kill it all. However, after pasteurization, a small number of harmless or beneficial, more heat resistant bacteria or bacterial spores remain.

Sterilization method:

There are many kinds of pasteurization procedures in use today. "Low temperature long time" (LTLT) processing is an intermittent process that is now used only by small dairy companies to produce some cheese products. "High temperature short time" (HTST) treatment is a "flow" process, usually carried out in plate heat exchangers, and is now widely used in the production of drinking milk. The products obtained in this way are not sterile, that is, they still contain microorganisms and require refrigeration during storage and processing. "Rapid pasteurization" is mainly used in the production of yogurt dairy products. There are two main Methods of pasteurization in international use:

One is to heat milk to 62~65℃ and keep it there for 30 minutes. Using this method, can kill a variety of growing pathogens in milk, sterilization efficiency up to 97.3%~99.9%, after disinfection of the residual only part of thermophilic bacteria and heat resistant bacteria and spores, but most of these bacteria are lactic acid bacteria, lactic acid bacteria not only harmless but beneficial to health.

The second method heats the milk to 75~90℃ and holds the milk for 15~16 seconds. The sterilization time is shorter and the work efficiency is higher. But the basic principle of antiseptic is, can kill pathogenic bacterium can, temperature is too high can have more nutrition loss instead.

Process flow:

Pasteurization machine is the temperature controller set PU value to convert into the actual control temperature curve of the water tank in each temperature zone, in order to accurately control the temperature change of each temperature zone through temperature detection. The main drive motor drives up and down the two layers of the bottle chain network will once the material through three temperature zone step by step heating preheating, and two temperature zone sterilization and three temperature zone step by step cooling and cooling process.